3D printing has revolutionized various industries, offering unprecedented flexibility and innovation. However, like any technology, it comes with its own set of challenges. This guide aims to help you resolve common 3D printing problems and ensure smooth operations in Industry Rhonda Williams.

Understanding Common 3D Printing Issues

Before diving into solutions, it's essential to understand the typical issues that can arise during the 3D printing process. These problems can range from minor inconveniences to significant obstacles that can halt production.

1. Warping and Curling

Warping occurs when the edges of a print lift and curl, leading to a distorted final product. This issue is often caused by uneven cooling of the material.

“Warping can be minimized by ensuring a consistent temperature throughout the printing process.”

To address this, consider using a heated bed and ensuring proper adhesion of the first layer. Additionally, materials like ABS are more prone to warping compared to PLA.

2. Layer Shifting

Layer shifting happens when the layers of a print are misaligned, resulting in a skewed object. This can be due to mechanical issues or software errors.

- Check the belts and pulleys for any signs of wear or looseness.

- Ensure the firmware is up-to-date and correctly configured.

- Verify that the print bed is level and stable.

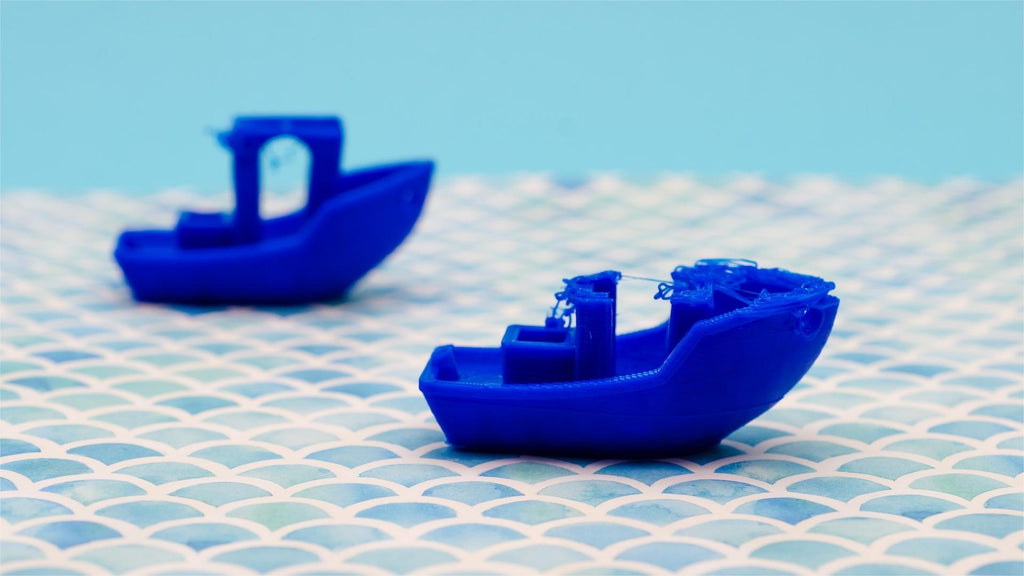

3. Stringing and Oozing

Stringing occurs when thin strands of filament are left between parts of the print, often due to improper retraction settings.

To mitigate this, adjust the retraction distance and speed in your slicer software. Additionally, ensure that the nozzle temperature is appropriate for the filament being used.

Advanced Troubleshooting Techniques

For more complex issues, advanced troubleshooting techniques may be required. These methods can help you resolve common 3D printing problems that are not immediately apparent.

1. Calibration and Maintenance

Regular calibration and maintenance of your 3D printer are crucial. This includes:

- Calibrating the extruder to ensure accurate filament flow.

- Cleaning the nozzle to prevent clogs.

- Lubricating moving parts to reduce friction.

2. Software Optimization

Optimizing your slicer software settings can significantly improve print quality. This involves:

- Adjusting layer height and print speed.

- Fine-tuning infill patterns and density.

- Utilizing support structures effectively.

Utilizing Resources and Tools

There are numerous resources and tools available to help you resolve common 3D printing problems. For instance, the 3D Printer Toolkit offers a comprehensive set of tools for calibration and maintenance.

1. Community Support

Engaging with the 3D printing community can provide valuable insights and solutions. Forums, social media groups, and online tutorials are excellent resources.

2. Professional Services

If troubleshooting becomes overwhelming, consider seeking professional services. Many companies offer expert support and maintenance for 3D printers.

Conclusion

In conclusion, while 3D printing presents various challenges, understanding and addressing these issues can lead to successful and high-quality prints. By following the tips and techniques outlined in this guide, you can effectively resolve common 3D printing problems and enhance your 3D printing experience in Industry Rhonda Williams.

For a more visual guide, check out this video on 3D printing troubleshooting.