Asbestos ridges are widely used in construction and industrial sectors as roofing and cladding materials due to their durability, weather resistance, and affordability. They are particularly popular in developing regions where cost-effective building solutions are in demand. Despite the ongoing debates about asbestos usage due to health concerns, the material remains a key component in various applications, provided that manufacturing adheres to safety regulations. Setting up an asbestos ridges manufacturing plant presents a significant opportunity to cater to the growing demand in construction and infrastructure projects.

Overview of the Manufacturing Process

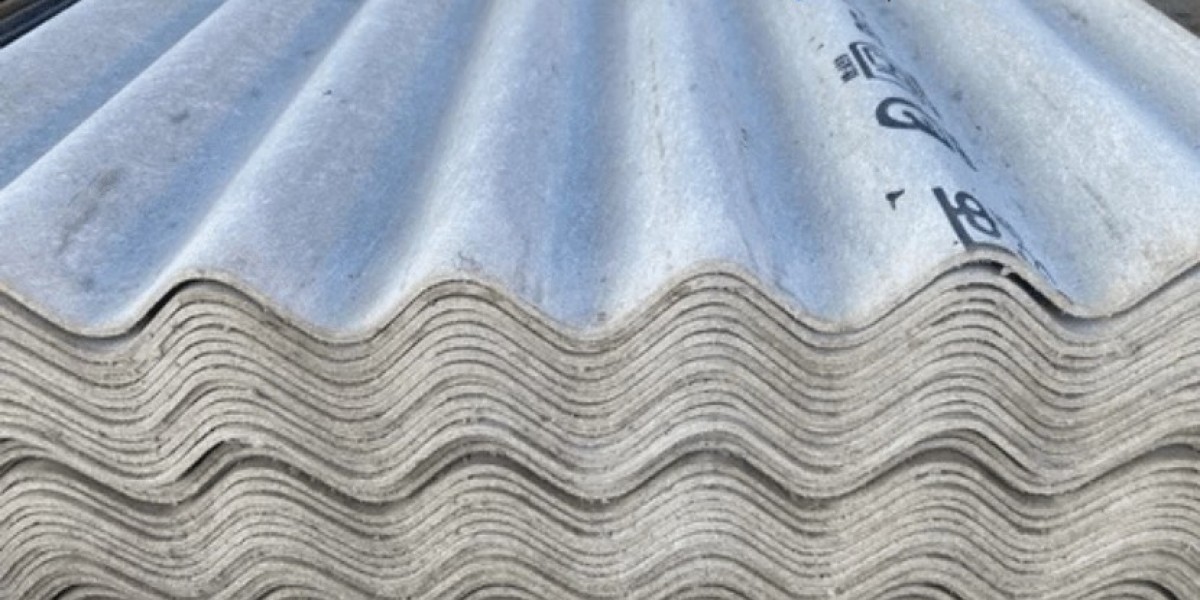

The production of asbestos ridges involves combining asbestos fibres with cement and water to create a durable and weather-resistant material.

Key stages in the manufacturing process include:

- Raw Material Procurement: Asbestos fibres, cement, and other additives are sourced from reliable suppliers.

- Mixing and Blending: The raw materials are thoroughly mixed to form a homogenous slurry.

- Moulding: The slurry is poured into ridge-shaped moulds and shaped to the desired specifications.

- Curing: The moulded ridges are cured in controlled environments to ensure strength and durability.

- Quality Testing: Each ridge is tested for load-bearing capacity, weather resistance, and compliance with industry standards.

- Packaging: The finished asbestos ridges are packaged securely for transportation and distribution.

Automation in mixing and moulding processes enhances production efficiency and ensures consistent product quality.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/prefeasibility-reports/asbestos-ridges-manufacturing-plant-project-report/requestsample

Plant Setup and Infrastructure

Establishing an asbestos ridges manufacturing plant requires specialised equipment, adherence to safety protocols, and compliance with environmental regulations.

Key infrastructure requirements include:

- Mixing Units: High-capacity mixers to blend raw materials uniformly.

- Moulding Machines: Equipment designed to shape ridges accurately.

- Curing Chambers: Controlled environments for curing products to achieve maximum strength.

- Quality Control Labs: Facilities equipped to test durability, resistance, and safety compliance.

- Storage Facilities: Dedicated spaces for raw materials and finished goods to ensure safety and quality.

- Packaging Units: Systems for efficient and secure packaging of asbestos ridges.

Applications and Market Demand

Asbestos ridges are versatile construction materials with applications in various sectors, driving their demand in the global market.

Key applications include:

Roofing Solutions:

Used in industrial, residential, and agricultural buildings for cost-effective roofing solutions.Wall Cladding:

Provides weather-resistant cladding for industrial and commercial structures.Drainage Systems:

Utilised in creating durable water drainage channels in construction projects.Fencing:

Employed as a sturdy and affordable material for boundary walls and fencing.Temporary Structures:

Widely used in creating temporary shelters and storage units.Export Markets:

Significant demand exists in developing countries where asbestos materials are still widely used.

Regulatory and Environmental Considerations

The production of asbestos ridges involves strict compliance with regulatory guidelines to ensure worker safety and environmental protection.

Key considerations include:

- Worker Safety: Providing protective equipment and training employees to handle asbestos safely.

- Dust Control: Implementing measures to minimise airborne asbestos fibres during production.

- Waste Management: Ensuring safe disposal or recycling of waste materials to reduce environmental impact.

- Regulatory Compliance: Adhering to local and international standards for asbestos use and manufacturing.

- Product Labelling: Including clear warnings and usage instructions to inform end-users of safety precautions.

Cost Factors and Investment

Setting up an asbestos ridges manufacturing plant involves costs related to infrastructure, machinery, raw materials, and operational expenses. Additional investments in research and development, certifications, and marketing are essential for establishing a competitive edge in the market.

Conducting a feasibility study helps assess market potential, resource allocation, and potential challenges. Collaborating with suppliers and industry experts can streamline operations and improve efficiency.

Features of a Modern Manufacturing Facility

Modern facilities for asbestos ridges production integrate advanced technologies and sustainable practices to ensure efficiency, quality, and safety.

Key features include:

- Automation: Enhances production speed and ensures consistent product quality.

- Dust Control Systems: Minimises the release of asbestos fibres into the environment.

- Energy Efficiency: Utilises energy-saving equipment to reduce operational costs and environmental impact.

- Real-Time Monitoring: Tracks production parameters to optimise efficiency and detect issues early.

- Sustainability Practices: Focuses on waste reduction and recycling of by-products.

Challenges and Opportunities

The asbestos ridges market offers significant growth potential but also presents certain challenges:

- Health Concerns: Ongoing debates about asbestos-related health risks have led to regulatory scrutiny in many regions.

- Market Competition: The industry is competitive, requiring innovation and cost-effective production methods.

- Regulatory Restrictions: Compliance with stringent environmental and safety regulations requires continuous investment.

Opportunities include targeting regions where asbestos products are still in high demand, developing innovative asbestos substitutes, and adopting eco-friendly practices to align with global sustainability goals.

Operational Best Practices

Efficient operations are critical for the success of an asbestos ridges manufacturing plant. Recommended practices include:

- Routine Maintenance: Ensures machinery operates efficiently and minimises downtime.

- Employee Training: Equips workers with skills to handle materials safely and maintain production standards.

- Quality Assurance: Implements stringent testing at every production stage to ensure product reliability.

- Inventory Management: Balances raw material procurement with finished product demand effectively.

Future Prospects

The demand for asbestos ridges is expected to persist in regions where cost-effective building solutions are prioritised. Manufacturers focusing on innovation, sustainability, and compliance with safety regulations will be well-positioned to capture this market and establish a strong presence.

Establishing an asbestos ridges manufacturing plant presents a significant opportunity to contribute to the construction sector while addressing the demand for durable and affordable building materials in the global market.